Strip-tiller Adam Nechanicky and his father, Mark, take pride in getting the most production from their 500-acre corn and soybean operation near Buckingham, Iowa.

Transitioning from conventional tillage practices to strip-tilled corn 7 years ago, the Nechanickys have meticulously modified their equipment setups and fertility approach to improve performance and productivity.

“With our fairly hilly ground and variable soil quality, one of the biggest motivations for strip-till was to be more efficient with our field operations and fertilizer application,” Adam says. “On our worst ground, we have nothing but rocks and clay, but on our best ground we can probably hit 300-bushel corn.

“Our goal with strip-till is to even out our variability and put our fertilizer where the seed is.”

Since making the move to strip-till, the Nechanickys have seen improved emergence and plant health in traditionally lower-producing fields, and more consistent 200-bushel-per-acre corn yields.

Evolving Equipment

The Nechanickys started with a 12-row B&H toolbar, which Adam admits was a relatively labor-intensive entry into strip-till equipment.

“It was designed like an ‘A’ frame and had six units in the front and three rows on each wing, with the dry fertilizer box in the center,” he says. “I designed a three-point assembly kit and brought all the row units up front to make it more compact, which made it easier to maneuver.”

MODIFICATION MINDED. Buckingham, Iowa, strip-tiller Adam Nechanicky says he’s a big believer that you don’t find a piece of equipment off the shelf, or simply adopt a practice,” he says. “You adapt it. I’m always changing things to make it work the best it can in our operation,” he says. |

They initially used a 215 horsepower, two-wheel drive Case IH 1570 tractor to pull their strip-till bar, but upgraded to a New Holland 8970 with a Trimble Autopilot automated steering system and Ag Leader Insight monitor.

One of the first lessons the Nechanickys learned was that auto-steer pays in strip-till.

“That first year driving the Case IH tractor, I’d be constantly looking behind me to try and stay on the strips,” Adam says. “Once we invested in the auto-steering system, we saw a big difference in accuracy of building strips in fall and being able to come back and plant into them in spring.”

They also saw measurable fuel savings moving from multiple field passes in conventional tillage to a one-pass system with strip-till. Adam estimates using one-third less the fuel to cover the same number of acres.

But their original strip-till unit began to wear down as it struggled to build fall strips into soybean stubble in damp fall conditions.

“It was a nightmare because the trash-whipper settings and row units were so rusted it was hard to make adjustments,” he says. “We’d spend half a day beating it with a hammer because we weren’t moving enough residue and the machine would plug and make a mess.”

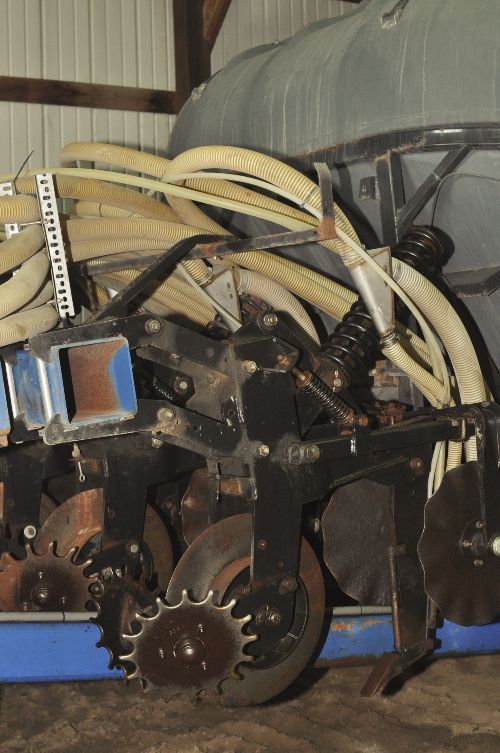

They moved to a 16-row Progressive toolbar with Remlinger row units and a mounted 6-ton Montag dry fertilizer bin. They also purchased a Caterpillar Challenger with tracks to pull the unit.

In order to get the Remlinger row units to mount properly, Adam used a local fabricator to build brackets to hold the units and provide enough clearance between the fertilizer box.

“My only concern was that it was going to be a little tight, because the original brackets were made for a 6-by-6-inch bar and we have a 7-by-7-inch bar,” Adam says. “I wouldn’t mind having rolling baskets, but there’s no room.”

Adam says he prefers the Remlinger setup because it’s more adjustable and the row units do a nice job of clearing residue from the strip. They feature floating trash whippers with spiked wheels, which are less aggressive than the setup on the Nechanickys’ first strip-till unit.

“We used to just have notched, concave discs on the old unit, and when we set them down in the dirt they tended to create a rut — especially with fall strips,” Adam says. “There was a much higher chance of those strips washing out. I like the floating trash whippers better because they move residue, but aren’t plowing at all.”

Spring Vs. Fall

Strip-tilling primarily in fall, Adam builds berms about 8 inches wide — although he would prefer to go narrower in the future — to place fertilizer closer to the seed. “I’m not strip-tilling for the tillage aspect. I want to get my fertilizer in the ground, down about 6 inches,” he says.

EYE ON AGRESSIVENESS. Two years ago, the Nechanickys moved to a 16-row Progressive toolbar with Remlinger row units and a mounted 6-ton Montag dry fertilizer bin. Adam says he prefers the setup because it’s more adjustable and the row units do a nice job of clearing residue from the strip. |

Adam also custom strip-tills about 1,000 acres for area farmers and that work, combined with an early winter in 2013, forced him to strip-till their own farm this past spring in wet conditions, which posed problems.

“We used a ¾-inch wide anhydrous shank with a 1-inch point and it pulled extremely hard,” he says. “I think that was too aggressive for spring because we brought up a lot of moisture and mud and ended up cleaning off the closing discs every 5 acres because they were caked with 4-to-6 inches of mud.”

After the corn was head high, strong winds flattened some of the spring strip-tilled fields, which Adam attributes to the strips being too mellow to hold the roots. If he is forced to strip-till in spring again, he plans to use a standard mole knife and not go as deep into the ground so the row units will pull easier through the field.

Fine-Tuning Fertility

The Nechanickys no-till soybeans and experimented with applying removal rate of phosphorous and potassium in the fall with their strip-till rig, and also fertilized for the following season’s soybean crop. But the strategy proved to be more trouble that it was worth.

“We were putting down more than 500 pounds of phosphorus and potassium and that was just killing our productivity,” Adam says. “We’d maybe get 20 or 30 acres and have to refill. We didn’t really see any yield benefit either.”

PLANTING PREFERENCES. Last spring, the Nechanickys purchased a 16-row John Deere 7000 planter bar with Kinze 3000 series row units, Precision Planting vacuum meters, Graham electric drives and Yetter Sharktooth trash whipper with Precision Planting CleanSweep air cylinders. |

They’ve since moved to applying about 250 pounds of potash and 200 pounds of anhydrous ammonia in fall with the strip-till rig. For soybeans, they broadcast apply phosphorous and potassium in the fall, but Adam is concerned about losing nutrients to surface runoff, especially with their rolling ground.

“There might be some value to spreading out that application since we were deep placing everything,” he says. “But I’m leery of broadcasting on top, because I do feel that some is lost.”

The Nechanickys don’t apply any fertilizer with the planter, but Adam says they may incorporate some additional applications in the future, to kick-start their corn crop in spring.

“We’ve had pretty good luck making all our applications with the strip-till unit, but we have a nitrogen toolbar for our sprayer that we may use for sidedressing in the future,” he says. “Our planter is also set up for liquid in-furrow application and next year, we may try applying 2 or 3 pounds of nitrogen to give those corn plants an initial boost.”

Planter Adaptations

Last spring, the Nechanickys purchased a 16-row John Deere 7000 planter bar with Kinze 3000 series row units, Precision Planting vacuum meters, Graham electric drives and Yetter Sharktooth trash whipper with Precision Planting CleanSweep air cylinders. Although Adam felt the setup was close to perfect, he still made some modifications to the row units to improve overall performance.

“We put on spiked press wheels to replace the rubber ones to help improve seed-to-soil contact, which was an improvement over our previous setup,” Adam says. “I’m also thinking of taking the CleanSweep air cylinders off the planter and making brackets for the trash whippers on our strip-till rig for corn-on-corn to move residue a little better.”

Adam says he’ll continue to modify their planter and strip-till unit in the future, because there are always improvements than can be made to become more efficient.

“I’m a big believer that you don’t find a piece of equipment off the shelf, or simply adopt a practice,” he says. “You adapt it. I’m always changing things to make it work the best it can in our operation.”