Injecting manure into strips allows more efficient use of manure, increases yields and creates a positive public perception of farmers.

Strip-tilling and applying manure simultaneously may make as much sense as other dynamic duos in agriculture, like corn and soybeans, ham and eggs and "rain makes grain."

Combining these tasks can save the time and money of an extra trip, while reducing commercial fertilizer costs, increasing yields and protecting the environment, say several farmers who have tried the practice.

FINDING SUCCESS. After strip-tilling manure in the fall, Aurelia, Iowa, farmer Dana Sleezer plants corn into the strips with the help of RTK guidance.

A One-Pass System

Dana Sleezer started strip-tilling with manure years before many people really talked about it, but that was a two-pass system.

"We had the cover discs on the back of the honey wagon," says the Aurelia, Iowa, corn and soybean grower, who also raises hogs farrow-to-finish. "We would go back with the strip-till machine after applying manure.

"In 2002, we started with a conservation tillage/no-till/strip-till system to apply manure. We would put manure down with six cover discs. But we didn't get 100% coverage.

"Then we went to strip-till behind the manure tank, which took two passes. In the fall of 2006, we decided it made sense to do it at the same time."

Then Sleezer added six Ag Systems' strip-till row units with 30-inch spacings on the honey wagon. He currently has a 7,300-gallon Houle tank with a six-row-unit toolbar, but will be switching to a 9,500-gallon Houle tank with an eight-row-unit toolbar.

Sleezer strip-tills and applies manure in the fall for first-year corn after soybeans and continuous corn.

He runs a lot of half-mile-long rows with one round equaling 1 mile. He applies roughly 3,900 to 4,000 gallons per acre of finishing manure.

With gestation manure, he applies 7,800 to 8,000 gallons per acre in a half-mile pass because the nutrient value is not as high as the finishing manure.

"Because of that, we apply according to the analysis, which equals twice the rate for gestation manure compared to finishing manure," Sleezer says. "That's why the tank-to-row-unit ratio works so well."

Sleezer works hard to minimize compaction. When he makes a 1-mile round, he's not traveling over the same ground twice. He's making two side-by-side passes.

"We always start on the headland and end on the same headland," Sleezer says. "A lot of people will stop in the middle of the field, turn around and drive back," he says.

Finding A Working System

Building berms while applying manure is a work-in-progress.

"The system works great, if you are able to do it," Sleezer says. "But I don't know how it would work on contours. Our fields are gently rolling - 1% to 2% slope and mainly straight.

WORK IN PROGRESS. Sheldon Stevermer, a Minnesota strip-tiller and hog farmer, strip-tilled manure last fall using Dawn Equipment's new Anhydra 6000 fertilizer coulter on the manure tanker. To make this practice work effectively, Stevermer says he will need to add RTK guidance on the tanker or wagon, a rate-control flow valve and a good distributor and chopper.

"We use RTK guidance. We just come back and plant right on top of the strips in the spring."

The biggest reason Sleezer switched to his current system of manure application was to get complete closure of the strip.

"We inject manure about 8 to 10 inches deep, so there is coverage and a better perception from the public. The odor is considerably lower than the system we previously used," Sleezer says. "The fields still have a lot of residue out there when we are done."

Everything is recorded when applying manure with an Ag Leader Insight monitor, which logs all the rates and locations. The Iowa Department of Natural Resources requires that he record all manure application data, including the location, section field, rate, building site and wind speed.

"We're really concerned about conservation practices," Sleezer says. "Our goal is to keep all the soil and the nutrients in the field where they can be used. All of our creeks have filter strips and we have grass waterways in the fields where water runs.

"We watch our return on investment and our commercial and hog manure fertilizer is a big part of that. We don't want to put any nutrients down where we could lose those assets."

In addition to the manure, he sprays 30 pounds of 28% nitrogen over the top. The last couple of springs, he says it's been cold and he doesn't think he got the nitrate conversion from the manure in the quantity he needed in the early part of the growing season.

"Because of the cool soils, you really have to get the trash out of the way when you plant and make the strip black, especially in corn-on-corn," Sleezer says. "If you don't, the corn doesn't emerge that evenly.

"I don't have residue managers on the honey wagon, but have them on the planter. When you make a black strip in the spring when planting, it attracts the sun and helps raise the soil temperature."

Strip-Till Manure Study

David Legvold, a Northfield, Minn., corn-and-soybean grower, turned to strip-tilling manure in 2006 to find a way to apply liquid hog manure while preserving crop residue.

Legvold also wears another hat. As executive director of the Cannon River Water Partnership, Legvold wrote two successful applications for grants to the Minnesota Pollution Control Agency (MPCA).

SWEET SYSTEM. The Honey Warrior is comprised of a chopper, distributor and row units that inject manure into the soil. It can be added onto manure wagons and tankers and allows operators to make strips and inject manure at the same time.

The grant money, along with in-kind contributions from local farmers, Monsanto seed representatives and ag equipment manufacturer Environmental Tillage Systems, supported two 3-year studies from 2005 to 2009, he says. These studies examined manure rates and yield response, application timing and the effect of strip-tilling with manure on water quality.

Legvold uses a Soil Warrior to make strips in the fall, placing all of the needed phosphate, potash and micronutrients in the strip. In the spring, he uses the Honey Warrior with its Mini Warrior ripple coulters to apply liquid hog manure in the strips. Then he returns and plants corn into the strips.

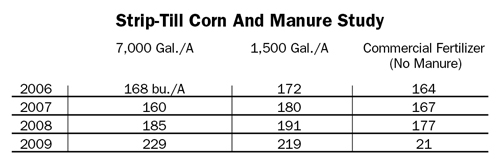

During the 3-year study, fall strip-till with 1,500 gallons per acre of manure applied in the spring out-yielded the land receiving 7,000 gallons of manure per acre. While the study ended in 2008, Legvold continued comparing rates and yield results in 2009.

"We got late-season rainfall in 2009 that allowed the nitrogen in the 7,000-gallon-per-acre trial to be converted to nitrate," Legvold says. "That corn yielded 229 bushels per acre, compared to 219 bushels per acre on the land that received 1,500 gallons per acre of manure in spring strip-till."

But it wasn't worth it economically to apply an additional 5,500 gallons of manure to increase yields 10 bushels per acre. He pays 3.6 cents per gallon for liquid manure, so the extra 5,500 gallons cost almost $200 per acre.

"Many farmers believe that they need to use enough manure to provide enough nitrogen for their corn," Legvold says. "Usually, that means you are way, way overapplying phosphorus. If it runs off your fields, phosphorus can grow algae. That's not a good thing to have in your lakes."

Better Public Perception

DOING THE MATH. In this study at Northfield, Minn., 7,000 gallons per acre of liquid hog manure was broadcast in the spring, and then tilled to incorporate it. Also, 1,500 gallons of manure per acre was strip-tilled in the spring back into strips made in the fall. Where commercial fertilizer and no manure was used, phosphate, potash and micronutrients were strip-tilled in the fall. In the spring, nitrogen was strip-tilled, followed by sidedressing when the corn was 12 inches tall.

Strip-tilling manure not only protects lakes, rivers and streams, but also can help farmers with public perception, Legvold says.

In Minnesota, the law requires manure applied to fields to be incorporated within 24 hours.

When the Honey Warrior was being developed in 2006, about 100 people from an area water-quality advisory council attended a field day where Legvold farms. Manure had been applied earlier that day with the Honey Warrior.

"You never would have known that they had just applied several thousand gallons of manure," Legvold says. "With the Honey Warrior, the manure is incorporated immediately. And if you give it a couple of hours for the field to dry, you can go back the same day and plant corn."

Legvold was getting an eight-row Mini Warrior this spring with 30-inch row spacing and a dry-fertilizer attachment. He'll pull it with a John Deere 4650 mechanical front-wheel-drive tractor. He'll use Trimble guidance.

Tips For Success

It takes several things to successfully strip-till manure into the large amounts of residue that continuous corn produces, Legvold says.

"It takes a machine that doesn't drag a shank through the soil, because that smears the sides of the trench and creates sidewall compaction," he says. "The machine must be able to dependably move through high residue without plugging up.

"And you need a grinder distributor that evenly distributes manure so the inside and the outside rows get the same amount of manure."

The Honey Warrior uses two ripple coulters that move through the soil at about 7 to 8 mph.

"The manure is placed in that turbulent zone of soil so when the manure settles down, it's nicely mixed together in the soil," Legvold says.

Low-Disturbance Manure Placement

Sheldon Stevermer began strip-tilling in 2003 and strips almost all of his corn and soybeans. Stevermer farms with his brother, Chuck, and their parents, Ray and Margaret. They also raise hogs, which produce about 120 acres worth of manure each year.

Last fall, the Stevermers spent 4 days working with the staff of Dawn Equipment to fine-tune the company's new Anhydra 6000 fertilizer coulter for manure incorporation.

They applied some manure from the 5,000-gallon tank at a 5-degree angle across soybean stubble, as well as on a bit of corn ground.

"That seemed to work pretty good because it left the field with low disturbance and should be easy to strip this spring," Stevermer says.

This spring, they will strip parallel to the field edges. Then they will plant their corn and soybeans using a 12-row John Deere 1760 planter with 30-inch row spacing. The planter has Dawn 1572 coulter-combo row cleaners.

"We were able to get the 6000 to do a nice job of putting up to 6,000 gallons per acre of gestation and farrowing manure into the ground with low disturbance," Stevermer says. "Nearly 90% of the manure was covered at that rate.

"At 2,500 to 3,000 gallons per acre, you couldn't even tell we had put manure on."

Stevermer says he went into the tests expecting to have an incorporator that would allow them to strip-till manure in 15-foot-wide swaths to match their 30-foot-wide strip-till applicator. He also planned to strip-till manure in the fall, then freshen the same zones in the spring with his Dawn Pluribus strip-till rig.

"After running it for a little bit, I quickly realized our goals were easier said than done," he says. "The large manure tank, which doesn't have implement steering, would slide down hills, essentially making the auto-steer on our tractor worthless.

"I had a very hard time consistently keeping 30 inches between the incorporator guess rows. I know we were running SF2 Deere guidance, but most of the error was coming from the tank moving horizontally."

Maintaining consistent application rates was a problem.

"We have a vacuum tank without any flow-control valving to control the manure application rate, so our application rate was essentially a guess on the tank pressure and ground speed," Stevermer says. "We also didn't have an accurate distribution manifold with a chopper, so there were different rates between strips.

"Too much manure will affect germination and root development."

Stevermer says he needs several things to make a strip-till manure application system work:

- Auto-guidance on the tank to keep the injector in the correct location.

- A rate-control valve to keep the application rate consistent and to change as speeds vary.

- A chopper and good distributor.

"These three items aren't cheap and, for our size of operation, probably not practical economically," he adds.

Most farm operations already use some form of auto-guidance, he says.

"To strip-till manure, it would be best to have RTK, which can add significant cost," Stevermer says. "My guess is that a rate-control valve, chopper and distributor would cost around $30,000. This doesn't include the strip-till units, because we need to have some kind of injector anyway, whether we are strip-tilling manure or not.

"Let's take 25% of the $30,000 for our annual machinery cost, or $7,500. I'd say we need to have the equipment cost in the $5-per-acre range.

"To really justify it, we would need to cover about 1,500 acres. We have enough manure for 120 acres, so our equipment costs would be very high."

Stevermer puts that in perspective.

"Granted, we are essentially getting the fertilizer for nearly free, so we can justify the higher machinery cost per acre," he says. "I think maybe a custom applicator may justify the additional equipment, but then I'm not sure if they would be able to tolerate the extra time required to do a satisfactory job."

For now, the Stevermers have opted to utilize a full-width, low-disturbance setup. Manure will be fanned on top and the incorporator will work it into the soil.

"We can either strip that a few weeks after application in the fall or in the following spring," he says. "I think strip-tilling manure can be done."

Making It Work

Minnesota strip-tiller and hog farmer Mark Bauer agrees with Stevermer. Bauer, the founder and president of Environmental Tillage Systems, began making the Soil Warrior and Honey Warrior for strip-till several years ago.

"The Honey Warrior evolved from the need I had as hog producer. I had a lot of hog manure and I wanted to put it in a zone. I was just looking to better manage my manure, which I see as a nutrient," Bauer says.

Applying manure and strip-tilling is a process of evolution, Bauer says, adding that everyone from the smaller to the mega producer is looking at it, but few realize it can be done.

Some farmers tell Bauer they want to change their farming practices to be more conservation minded, but manure hinders them.

"Others are just looking how to use the row units on the back of the manure tanks to incorporate manure," he says.

Much of the interest is coming from South Dakota, southern Minnesota and Iowa, where there are lots of hogs and dairy cows, Bauer says.

He and his wife, Sue, grow about 1,600 acres of corn and soybeans and lease out their hog barns. They apply the manure to their crop ground.

"I've been trying to figure out how to no-till and strip-till with manure for about 20 years," Bauer says. "I got tired of trying to modify other equipment, so I built my own machine.

"I have a wide variation of soils, ranging from sand and gravel to really heavy, mucky, cold soil."

Bauer battled high residue, fought erosion on hills and ran into rocks. Worst of all, he fought the weather. All too often, the weather won, beating up his no-tilled corn.

"No-till seems to be so weather sensitive," Bauer says. "Certain years, I looked like a genius. Other years, I was forced to plant in marginal conditions. I built this machine to handle any condition. Most of the time we strip-till manure in early November and we try to do spring application in early April.

"I've been forced to apply in May at 2,000 gallons per acre and plant 2 days later and still have had good results."

Lower Rates, Higher Yields

On corn, Bauer applies 1,500 to 1,800 gallons per acre of hog finishing manure. With nursery manure on corn ground, he applies 2,500 to 3,000 gallons per acre. He also applies 50 to 70 units of commercial nitrogen.

Bauer will only apply manure to ground to be planted into soybeans if the soil tests low in phosphorus. On these fields, he fall applies no more than 1,500 gallons of manure per acre.

He has been surprised during the last few years by the results of lowering rates and its effects on corn yields.

"The more I cut my manure application rates, the higher my corn yields are," he says. "In the last 5 years, our corn yields are running about 18 bushels per acre over the county average.

"Corn yields range from 230 to 260 bushels per acre and soybeans 65 to 75 bushels per acre."

While farmers may look at strip-tilling and applying manure for many reasons, it's important to look at economics, Bauer says.

"How many bushels of corn can you sell from every acre you plant?" Bauer asks. "We're trending into very exciting territory on our farm."

But there's positive news on the environmental impact of strip-tilling manure, Bauer says. He points to the research done by Legvold, as well as other research, that showed lower rates of manure increase corn yields.

On his farm, Bauer started by looking at the typical rate of applied manure and then cut it by 50% or more.

"It doesn't take that much manure to reach maximum economic return on corn," Bauer says. "Environmentally, it's a win-win. Farmers are environmentally sensitive, but the overall driving force in agriculture is economics.

"As we learn what we are doing with the economics of strip-till and how to economically better manage the nutrients from manure, the environment benefits, too."

MORE COVERAGE Compaction, Mud Are Challenges For Strip-Tilled Manure

Strip-tilling manure involves a number of agronomic and engineering challenges. Mike Petersen, precision-tillage agronomist for Orthman Manufacturing Inc., says working in mud when the soil is wet can create pockets or trenches, which may allow manure to move off fields into tile drains and bodies of water.

"When you go out in fields when it's wet with an 8- to 30-ton manure wagon and a large, heavy tractor, compaction occurs," Petersen says.

Petersen's perspective about compaction comes from more than 30 years of working as a soil scientist for the Natural Resources Conservation Service. During those decades, Petersen dug more than 1,000 pits in farmers' fields, looking at root growth and how tillage systems affected compaction and yields.

"The rule of thumb is that for every ton of axle weight, we can drive compaction 1 inch down in the soil, especially in wet conditions," Petersen says. "If the manure wagon weighs 30 tons, the compaction can go 30 inches deep. Without any mechanical alleviation, I've found compaction remaining over 30 years.

"It creates a number of problems. Soil aggregate stability falls apart, and you suffer more erosion losses, crusting and ponding of soils."

Getting the soil to seal as the strips are created can be difficult. Even when the soil is not wet in the fall, the combination of the soil and liquid manure can create buildup on sealing discs or coulters, Petersen says.

Despite the challenges that farmers and strip-tillers, in particular, face applying liquid manure, technological innovation will make the practice easier and more effective.

"I know we can make it happen," Petersen says.