For a typical farmer, accuracy is important. But, for strip-tillers, it’s make or break. Whether it’s ensuring planting and applying fertility exactly where the strips are or something more complicated like matching a 24-row planter to a 12-row strip-till rig, a strip-tiller has to know precisely where their strips are every single time they roll across the field. For this reason, RTK (real-time kinematic) technology is nearly everywhere in the practice. But not all solutions are created equal, and in RTK, equipment and procedure matter.

Put simply, DigiFarm’s Steve Riddle says RTK is “a technique to increase the accuracy of GPS signals with a fixed base sending corrections to a rover, which would be you and your GPS system in the field.” The method of delivering the corrections and orientation/distance of the base from the rover is where things get more nuanced, notes the 35-year precision ag veteran.

“The nice thing about determinant accuracy for RTK is that no matter the provider and what type of technology is being used, we all have the same rules that affect our accuracy,” he says. “I think most agree that for every 10 miles of distance between you and the nearest base station, you lose 1 inch of repeatable horizontal accuracy.”

Portable/Fixed Radio Bases

Radio-based RTK is the oldest technology of its kind with its own advantages and drawbacks, notes Riddle. Fixed-location radio RTK bases are often centrally located to a farmer’s operation and mounted permanently on a grain leg or tower of some sort. Portable bases can be collapsed and moved closer to the locations where they’re needed.

Both styles are limited by line-of-sight, meaning trees, foliage, buildings and terrain can disrupt the signal. Mounting the base on a high enough tower can mitigate this, adds Riddle, but it exposes them to weather events — they can be fried by lighting or knocked out of sync by high winds.

“RTK is a technique to increase the accuracy of GPS signals with a fixed base sending corrections to a rover…”

Riddle notes that few types of RTK can match the accuracy of portable radio bases simply because they can always be set up well within 10 miles of where the work is being done, thus providing the tightest corrections. However, there are several factors that make it more suited to one-off types of work like tile installation.

The portable bases need a remote power source, and they can be time consuming to take down and move when you exceed their range, says Riddle. Chief among the limitations for strip-tillers may be repeatability.

“If you try to use it for row crop farming applications for repeat passes throughout the year, the portable base has to be in exactly the same spot it was when you originally tilled,” Riddle says. “Even if you had a concrete post poured for it, if freeze/thaw cycles move it even 1/2 inch, you’re a 1/2 inch off your rows out of the gate.”

Despite limitations, they remain a popular option for farmers without many line-of-sight issues, adds Riddle.

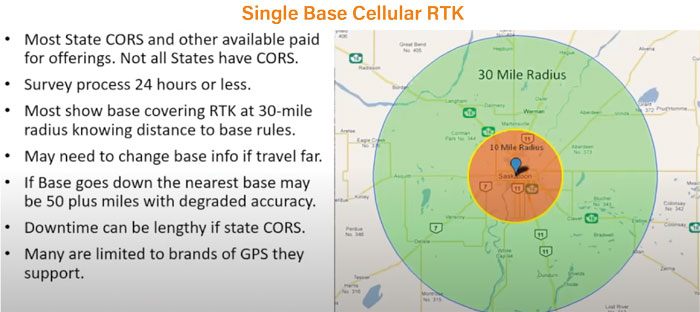

Single Base Cellular RTK

Often provided through a privately-owned or a state-run CORS (continuously operating reference station) system, single base cellular RTK are corrections provided from a cell tower. It’s stronger than radio in some respects as it doesn’t have line-of-sight limitations. Often, it’s a more affordable (free in some states) solution, but Riddle raises similar points about distance from the base.

BASE HIT. Like other forms of RTK, single base cellular has its pros and cons. Often provided through a privately owned or a state-run CORS (continuously operating reference station) system, it doesn’t have line-of-sight limitations, but its limited radius could hurt its repeatable accuracy, Steve Riddle says. Image: Steve Riddle

“A lot of the base coverage maps show a 30-mile radius, but if we go back to that distance rule, the signal is starting to degrade significantly outside of the 10-mile range,” says Riddle. “If you’re looking for repeatable accuracy, I would challenge using this, and certainly for vertical accuracy, you wouldn’t want to trust that much more than a few miles outside where that physical base is.”

Relying on a single tower not owned by the farmer could make unexpected interruptions particularly troublesome, too. Riddle notes that if the cell tower being used goes down, the nearest alternative may be 50 miles away — a distance that would significantly degrade accuracy.

“If it’s a state CORS network you may have to consider their downtimes,” says Riddle. “They might have a server problem or go offline for updates. It’s their discretion when they get back up and running. A lot of them are limited to the brands of the GPS that they support also.”

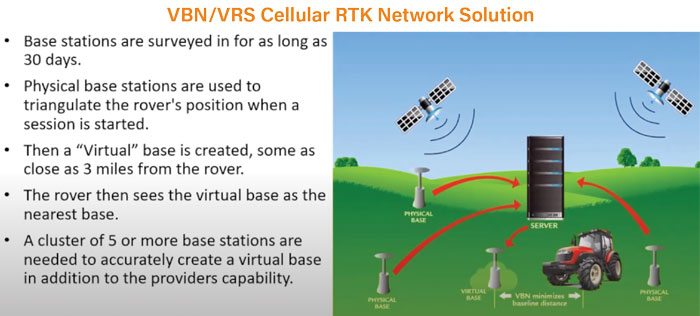

VBN/VRS Cellular RTK

Virtual Base Network (VBN) or Virtual Reference Station (VRS) cellular RTK is another solution that’s not line-of-sight restricted. Riddle notes that the bases need to be mounted at about the height of a typical two-story house and have a clear view of the sky. As with the single base cellular RTK, VBN/VRS may not work with all brands of GPS equipment.

Distinct from the other forms of RTK that rely heavily on a rover’s position in relation to the base station of choice, Riddle says VBN/VRS networks triangulate with a “cluster” of other stations so that the rover’s location can be precisely measured from multiple different reference points. Because of this type of interaction, virtual bases can be established sometimes as close as 3 miles from where the corrections are needed, providing a very high degree of accuracy, says Riddle.

BASES LOADED. The rover’s location can be precisely measured from multiple reference points with a VBN/VRS cellular network, establishing close virtual bases that provide a high degree of accuracy. Image: Steve Riddle

“There does need to be a minimum number of base stations in a cluster in order to create this,” says Riddle. “The general rule is 5 and they can’t be just in a straight line. They’ve got to be in somewhat of a cluster to be able to triangulate.”

A side benefit of a cluster of bases is that if one goes offline for any reason, the others in its network can pick up the slack. However, since the corrections are made via a cellular network, it’s possible for reception to blink in and out, which could cause an issue, but Riddle notes that the signal is being sent in the form of a data packet (akin to a text message).

“My rule of thumb is asking in your worst field where you constantly drop calls or can’t make a call — can you send a text without it failing to send?” Riddle says. “Because if it’ll send all the time and never fail to send, whether you’re going to use a modem or a Bluetooth piece and an iPad, that should be OK with what we need to do.”

Satellite RTK

Satellite, the newest form of RTK, eliminates the need for base stations and takes in signals from the Global Navigation Satellite Systems. Because of how the system works, Riddle remains apprehensive about the level of accuracy.

“They’re utilizing additional L Band satellite corrections so that there’s just more averaging that can take place,” Riddle says. “Make sure to communicate with the provider to be confident about the repeatability and timeline. Is it just for pass to pass? Is it limited time? Is it in-season or 9 months? What kind of time limitations are there?”

“For every 10 miles of distance between you and the nearest base station, you lose 1 inch of repeatable horizontal accuracy…”

Riddle notes that many new correction satellites are coming online all the time — specifically Russia’s GLONASS, Europe’s Galileo satellite positioning system and China’s BeiDou system. While he says it appears that a standard receiver can interact with these, Riddle says attention must be paid to the exact source of the positioning data in order to examine its repeatable accuracy.

“Firing up a new GPS unit in the field can be exciting because where an old antenna only picked up 12 satellite a new one might be seeing 28-30, and that’s awesome,” Riddle says. “But we still have to ask what we’re using at the base station levels. You may see that many, but they may not be being utilized in the RTK correction process.”

Sharing Data

Retrieving and storing the correction information for future use is one thing but sharing it across multiple platforms and receivers can be tricky if there’s a hodgepodge of equipment in the field. For this, Riddle says the NAD83 (North American Datum of 1983) and John Deere’s ITRF protocols used to share datum — a reference frame precisely representing a planetary position through geodetic coordinates. For 2 GPS units to use the same datum, they must precisely agree on their own orientation.

“NAD83 has some newer solutions coming out, but it’s the benchmark protocol for all GPS systems,” Riddle says. “This is the standard in the U.S., and everyone uses it except John Deere. Let’s say there are 200 master reference survey pins across the U.S. and Canada that everything originates to or from. When a surveyor is marking personal property or a fence line for house, it doesn’t even have to necessarily be in the field, but that all chases back to these master reference points.”

Making Sense of Different Types of RTK

Click here to watch a Strip-Till Farmer webinar replay featuring DigiFarm’s Steve Riddle. The precision ag expert helps growers develop a clearer understanding of the various types of RTK technology and better set expectations for repeated accuracy.

There will likely be changes soon for John Deere equipment, Riddle adds.

“Up until recently, John Deere has always used the separate ITRF, which is an international datum with a single reference point using the center core of the earth as a worldwide reference point to calculate from,” Riddle says. “What’s changing is John Deere’s SF-RTK (StarFire). It’s fairly new, but it’s satellite-based RTK.”

Still, sharing information across a “mixed fleet” can cause large variations.

“This is especially the case when you’re talking about somebody with a NovAtel or Trimble receiver sharing with a John Deere receiver,” Riddle says. “I’ve worked with a farmer who had a mixed fleet, and they were sharing guidance lines between their equipment. When they loaded them, they were off by 28-30 inches, and it was because of the different datums.”

For the immediate future, Riddle says farmers experiencing these issues will likely need to rely on conversion software that can manually manipulate the datum to account for the difference in protocols.