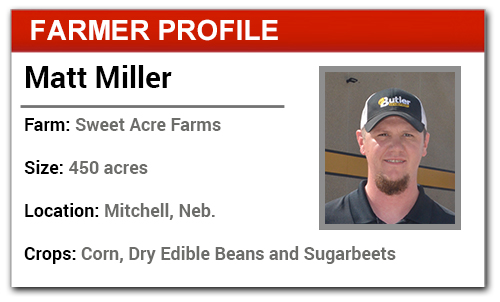

Matt Miller worked closely with his father-in-law, Randy Hoff, near Mitchell, Neb., getting his equipment set up for automatic guidance. It’s helped the 450-acre irrigated corn, edible dry beans and sugarbeet operation better leverage strip-till and made it easier to build strips and then stay on them at planting.

“There are tangible and intangible advantages associated with precision guidance,” says Miller, who also is a precision specialist at Butler Ag Equipment, a farm equipment dealership based in Fremont, Neb. “For us, the guidance meant we’d be less tired at the end of the day and there would be less variance in the guess rows. We’ve never got into figuring ROI on it, but it makes so much sense.”

Miller worked with Hoff to configure a Trimble EZ-Pilot assisted steering system in the tractor that pulls the 8 row Schlagel strip-till rig in the spring, sometimes just ahead of the planter. They adopted strip-till in 2008 and installed the auto-steer system 2009. It follows an RTK signal subscription through the local Case IH dealer.

In 2010, they installed a Trimble EZ-Steer assisted steering system on Hoff’s AGCO RT155A tractor that pulls their 8 row John Deere 7300 planter. “Our tractors are older and don’t have the valves for auto-steering systems, so these attach to the steering column and work well,” Miller says.

They plan to add auto-steer to their Tyler Patriot 150 self-propelled sprayer with 60 foot booms that they purchased this year, but have yet to venture into variable-rate seeding or fertilizer application.

Point of Pain: Compensating for Drift

While Miller has had plenty of experience working with other farmers overcoming their obstacles to successful precision farming implementation, his pinch point involved getting the precision guidance system adjusted for the strip-till rig’s side pull.

“Every piece of field equipment has some side pull and that is especially true on the strip-till rig,” he says. “It took some time and thinking to adjust the steering system to compensate for it.”

Miller says the process of compensating for drift is counterintuitive. “It took us a few hours in the field working with it and then following up with the planter to make sure we were getting there,” he says. “It turns out, the compensation needs to be in the direction of the drift, not against it. I wish drift adjustment systems were easier to configure.”

One advantage to Miller’s experience as a user and troubleshooter of technology is that he can understand farmers’ frustration when things don’t work.

“That’s only made worse when the dealer isn’t as responsive as the farmer would like,” he says. “It takes patience on both sides. We all have a time crunch and long days.”