As a farmer, you know that a successful planting season is crucial for a bountiful harvest. One way to ensure that your crops get off to the best start possible is by properly maintaining your seeder. In this article, we'll share some essential tips for conducting a thorough inspection of your seeder, and highlight the importance of regular maintenance to maximize your yield.

First and foremost, start with a visual inspection of the frame. Look for any breaks or damage, especially at weld points. Ensure that the frame is in good working condition before proceeding with any other checks.

Next, inspect the tires for proper pressure and condition. Having the right tire pressure is critical for ensuring accurate seed placement and preventing compaction.

Check your external weights too, to ensure they're securely mounted and suitable for the conditions you'll be working in.

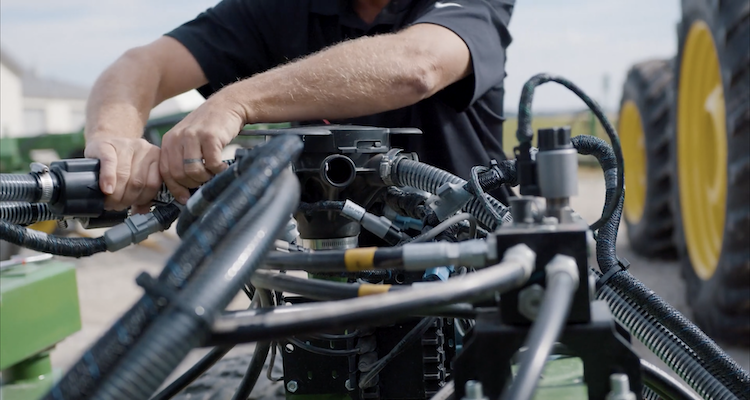

The seed delivery system is a critical component of your seeder. Therefore, it's essential to inspect your primary and secondary hoses thoroughly. Look for splits or crimps, especially where the seeder wings fold up, and watch out for dry rot. If the seeder sits in the sun, the hoses can become brittle, and you risk losing seed, fertilizer, or air pressure. This will impact seed delivery to that row or section. Additionally, if you're running fertilizer through the seeder, pay special attention to the tightest radiuses. Potash and ammonium sulphate are abrasive and can wear out the hoses' corners. Check that the hoses are long enough too. If they're too short, they may pull out when you push the openers down to maximum depth.

When it comes to testing airflow on your secondary line, our recommendation is to remove the secondary hose from the seed tubes on the two outside rows, as they have the farthest travel from the meter. Point the tube straight up and power on the fan at the ideal RPM. Engage the seed flow and blow seed through the system. You should be able to blow seed approximately 24 inches high out above the seed tube. If it's much more than 24 inches, bring your fan speed down to avoid wearing out your hoses faster. If you have less than 24 inches of seed blowing out of the hose, you could have blockage issues, especially if you're working with high rates of fertilizer and seed going through those secondary hoses.

In conclusion, a properly maintained seeder can significantly impact your crop yield. Make sure to perform regular inspections of your seeder, paying close attention to the frame, tires, weights, and seed delivery system. By taking these steps, you'll be well on your way to achieving a perfect stand this spring and avoiding regrettable yield loss. And remember, partnering with a Precision Planting Premier Dealer can provide additional expert insights and help you achieve optimal results. Find your local Precision Planting Premier Dealer at planterexpert.com.

To watch videos of all recommended annual maintenance checks, visit PrecisionPlanting.com/seedermaintenance.

Download the free Seeder Maintenance Guide. This guide includes a 1-sheet checklist, links directing you to the corresponding videos, and an overview of 8 key maintenance areas on your seeder.

The Planter Maintenance series is brought to you by Precision Planting.

For farmers who believe in better. Believing in better is a mindset to pursue excellence in everything you do. It’s welcoming opportunities to improve your farm and knowing that your best season is simply a starting point for this season. Precision Planting is for farmers like you who Believe in Better.