The closing assembly is a critical component of a seeder, responsible for pressing the soil around the seed to create the ideal environment for germination and emergence. However, if the closing assembly is not properly maintained, it can lead to inconsistent seed slot closure, resulting in uneven emergence and ultimately, reduced yields.

In this article, we will discuss the key components of the closing assembly and how to maintain them to ensure consistent seed slot closure and optimal plant growth.

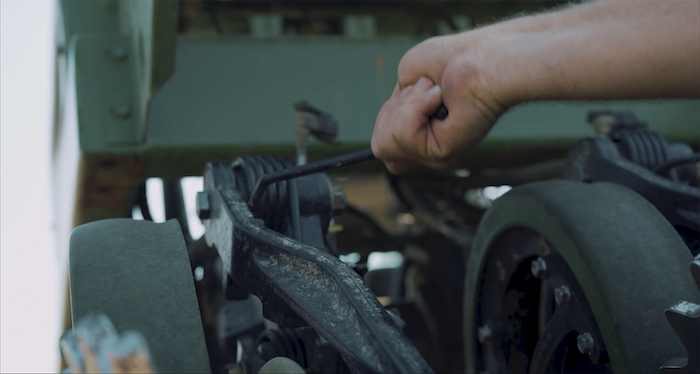

The Closing Wheel Arm

The pivot point of the closing wheel arm is a crucial component to check when inspecting the closing assembly. It is important to look for excessive travel at the back of the arm, as this could indicate that the bushings or pin have excessive wear.

Ideally, there should be no more than half an inch of total travel on the back of the closing wheel arm. If there is more than that, it is time to replace the bushings or pin to prevent further wear and ensure proper functioning of the closing assembly.

Ideally, there should be no more than half an inch of total travel on the back of the closing wheel arm. If there is more than that, it is time to replace the bushings or pin to prevent further wear and ensure proper functioning of the closing assembly.

The Spring

The spring in the closing assembly is responsible for providing tension to the closing wheel arm. It is important to check that there is good tension and that the spring is not broken or excessively worn at any point.

If the spring is not functioning properly, it can lead to inconsistent seed slot closure and uneven emergence. Therefore, it is important to inspect and replace the spring as needed.

The Closing Wheel Arm Pin

The closing wheel arm pin is the component that attaches the bolt to the closing wheel arm. There are two inner bushings inside the housing, and the pin rotates within these bushings. However, over time, the pin can wear excessively due to the arm pivoting up and down, as well as covering a lot of acres.

If the pin is excessively worn, it can translate to wear at the back of the arm, leading to inconsistent seed slot closure. It is important to check the pin regularly and replace it as needed to maintain a tight arm and ensure optimal performance of the closing assembly.

Partnering with a Precision Planting Dealer

Maintaining the closing assembly is essential to achieving optimal plant growth and yields. However, it can be challenging to keep up with regular maintenance and inspections, especially during the busy planting season.

That's where partnering with a Precision Planting Premier Dealer can help. Precision Planting Premier Dealers are experts in seeder maintenance and can provide guidance on the best practices for maintaining the closing assembly and other critical components of your seeder.

Additionally, they can recommend upgrades and enhancements to improve seeder performance, ensuring that you achieve your best yields and avoid regrettable yield loss caused by lack of maintenance. Find your local Precision Planting Premier Dealer at PlanterExpert.com.

To watch videos of all recommended annual maintenance checks, visit PrecisionPlanting.com/seedermaintenance.

Download the free Seeder Maintenance Guide. This guide includes a 1-sheet checklist, links directing you to the corresponding videos, and an overview of 8 key maintenance areas on your seeder.

The Planter Maintenance series is brought to you by Precision Planting.

For farmers who believe in better. Believing in better is a mindset to pursue excellence in everything you do. It’s welcoming opportunities to improve your farm and knowing that your best season is simply a starting point for this season. Precision Planting is for farmers like you who Believe in Better.