As with any new practice, many growers considering a switch to strip-till for corn and soybeans may question what the eventual payoff will be.

But there is an abundance of research that suggests strip-till is a viable practice that can improve soil health through reduced disturbance, reduce operating costs and deliver comparable yields, even in cold climates, says Jodi DeJong-Hughes.

The University of Minnesota Extension regional educator, whos’ been an outspoken advocate of strip-till, believes the practice has value in her geographic area marked by short growing seasons and chilly spring planting conditions. She offers hard data to counter the two most popular reasons growers give for not adopting the practice.

Strip-till wins the economics test for both corn and soybeans, with lower input costs as it reduces soil erosion and improves water infiltration over tilled ground, says DeJong-Hughes, who oversees scientific studies of tillage systems as they relate to soil erosion and economic returns for growers.

After hundreds of on-farm studies, and thousands of miles of travel to grower meetings and conferences preaching proven benefits of reduced tillage, she says hesitant growers consistently default to: “It won’t warm up or dry out in the spring” and, her perennial favorite, “My yields are going to suffer.”

Planting Conditions

In a four-year study at three North Dakota sites in sand, silty-clay and clay loam soils, researchers took weekly soil moisture and temperature readings in fields under no-till, vertical tillage, chisel-plow and strip-till management, up through planting.

The average soil temperatures at planting depth on planting day for the treatments at all three locations over four years showed strip-till at 51 degrees F, compared with 50 degrees F for chisel-plow treatments.

“The benefits of strip-till for corn — reduced soil erosion & improved soil structure & related water infiltration — are priceless…”

It showed similar results with strip-till to conventional farming, and only a third of the field was being disturbed — “saving significant money in doing it with only one pass,” she says. No-till and vertical tillage showed an average of 42 and 47 degrees, respectively — much like surface temperatures measured just under residue, which averaged 45 degrees F.

Strip-till and chisel-plow averages for soil moisture at planting in the trials also showed nearly identical performance, again, with strip-till providing erosion control and many soil-building and soil-health attributes when compared with the plow.

MONEY-MAKER. Strip-till wins the economics test for corn and soybeans, with lower input costs as it reduces soil erosion and improves water infiltration over tilled ground, says Univ. of Minnesota regional educator DeJong-Hughes. Jodi Dejong-Hughes

“We figure 50% moisture readings as ‘saturated’ and the chisel-plow and strip-till treatments showed averages of 19% and 18%, respectively, on planting day,” DeJong-Hughes explains, “They were significantly drier than the no-till treatment at 32% and vertical tillage at 25%.

With both shank and coulter strip-till rigs, not only does the soil warm up and dry out under strip-till, but “you have cooler and wetter conditions in the soil to the side of the row for later in the season,” she says. “It’s win-win.”

Yield Performance

Traditionally, the importance of tillage effect on corn and soybean yields, has been overestimated, DeJong-Hughes says, pointing to nearly two decades of comparisons that show there’s mostly very little difference in yields in full-field tests comparing aggressive tillage, medium tillage and light tillage.

“In North Dakota and a couple of spots in Minnesota — over 18 site years — 44% of the time, no-till corn out-yielded or yielded the same as the other two tillage methods,” she says. “Strip-till performed better or the same 44% of the time, and chisel-plow fields did better or the same 12% of the time.”

“Strip-till & chisel-plow averages for soil moisture at planting in the trials also showed nearly identical performance…”

In similar trials on soybeans over 17 site years in both states, 76% of the time, there was no statistically-significant difference in yields when strip-till was used versus chisel-plow.

“This tells us the differences in yield can much more likely be attributed to weather rather than what tillage method we’re using,” she explains.

Economic Comparison

Another reason DeJong-Hughes will tell you she’s “Still Crazy for Strip-Till After All These Years” is pure economics.

In the 2023 Farm Business Management report from the University of Illinois, economists there projected the cost of production under various tillage methods for corn. The annual report used a hypothetical 1,400-acre farm and the purchase price for all new equipment.

The new equipment cost was used to provide an ‘apples to apples’ comparison to weed out the on-farm variables that occur when comparing operations with equipment of different ages and depreciation schedules. With everything assumed to be brand new it provided the same basis on which to base the figures.

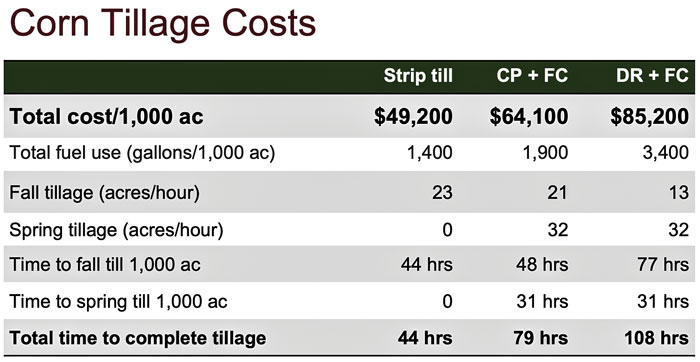

The equipment estimates for 1,000 acres of production were $49,200 for strip-till, $64,100 for chisel-point/field cultivator, and $85,200 for disc ripper/field cultivator. Assumptions also included $3.50 diesel fuel, $21 per hour labor rates, new tractor and implement overhead (including higher costs for reduced tillage planting), and related operational costs such as depreciation, interest, insurance, housing and repairs.

FUEL SAVINGS. In the 2023 Farm Business Management report from the Univ. of Illinois, economists projected the cost of production under various tillage methods for corn. When seasonal tillage costs for production on 1,000 acres were compared for strip-till, chisel point/field cultivator (CP + FC) and disc ripper/field cultivator (DR + FC), strip-till would have burned 500 gallons of fuel compared with 2,000 gallons of fuel for the more aggressive tillage treatments. Dave Franzen, North Dakota State University

When seasonal tillage costs for production on 1,000 acres were compared for strip-till, disc ripper/field cultivator and chisel point/field cultivator, strip-till would have burned 500 gallons of fuel ($1,750) compared with 2,000 gallons of fuel ($7,000) for the more aggressive tillage treatments.

Time, too, is valuable, and strip-till also proved its worth on the clock. Using the same scenario, estimated time in the field for strip-till was 35 hours, compared with 64 hours for the conventional treatments. At $21 per hour, that’s $740 compared with $1,340, or nearly half the per-acre cost in labor.

DeJong-Hughes says this shows the “significant economic potential” for moving to strip-till from conventional tillage, particularly when one considers 92% of the time, strip-till yields the same as using a disc ripper or chisel-point with the required field cultivations. In comparison, no-till provides the same yields in only about 45% of seasons.

“To me, the benefits of strip-till for corn — reduced soil erosion and improved soil structure and related water infiltration — are priceless,” she says. “This is particularly significant when studies show tillage destroys soil structure and increases soil erosion by 3-20 tons per acre per season, and, if you have to buy lost topsoil, economists estimate you’ll pay $25 a ton — not counting the cost of lost productivity, carbon and crop nutrients.”