Since becoming the sole operators of their family’s Homewood Farms in 2000, Dan Lane and his wife, Jennifer, have used precision practices and conservation tillage to significantly boost corn and soybean yields as well as overall farm income.

In 2018 the 1800-plus acre operation located north of Columbus, Ohio, was part of an American Farmland Trust and local NRCS Conservation District study that showed the couple realized an overall $56 per acre boost in net income because of their adoption of soil health practices including strip-tillage, banding nutrients and, at that time, the introduction of cover crops into the rotation.

“I’ve gotten away from cover crops because we realized the residue was interfering with our corn emergence,” Lane says. “We need clean strips for top uniform emergence. We started using more humates to maintain and build organic matter and release tied-up nutrients.”

Still, at the time of the study, Lane says average corn yields per acre had jumped from roughly 145-170 bushels per acre when his family was farming conventionally to 195-210 bushels per acre across the operation — and yields have gotten even better over the past 5 years.

“Up through the 1990s, we did little to build the soil. We did some soil testing, but we usually just applied the same fertilizer year after year. We were low in phosphorus and potassium,” he says. “Also, we ran a chisel plow over the entire operation every year and came back with two field-cultivator passes for both corn and soybeans.”

Lane knew he had to make changes.

HOMEBUILT HYBRID. The conversion of a Kinze 3600 planter to a strip-till bar equipped with StripCat row units gave Lane a tool he could safely transport on local roads and enabled dry-fertilizer banding. Photo: Dan Lane

“We’re in the fastest growing area of Ohio and it became apparent we didn’t know when access to rented land would be gone because of development,” he says, noting he also realized he needed increased yields and fewer expenses to be successful with the farm going forward.

Strip-Till Solutions

By 2003, Lane became a strip-tiller with a modified Brillion Zone Commander pulling a Progressive dry box banding fertilizer. Later he bought a Case IH Nutri-Placer 12-row-30-inch and used the same dry box on it. Transportation issues, however, convinced him he needed something more easily transported on local roads than the Nutri-Placer.

To meet that need, he converted a Kinze 3600 16-row-30-inch planter and equipped it with StripCat row units, which feature cutting discs and rolling baskets.

“I’d never been a fan of broadcasting fertilizer, and I was beginning to see equipment for banding, and that’s what drew me to strip-till,” Lane says. “After we began farming on our own, we did a lot of test strips and soil testing with broadcast fertilizer. The results never showed us much difference, so I started banding.

“With the Kinze conversion, I could band fertilizer with the application equipment as we built strips, and we ran it spring and fall behind an in-row ripper with GPS RTK guidance,” he says. “We still use that machine today, as well as a 16-row-30-inch AgSynergy shank-equipped strip-till bar with rolling closer wheels and a mounted 9-ton Montag dry fertilizer unit.

“Banding allows us to grow better yields on poorer soils because it enables us to increase base saturations in the root zone, instead of building the whole soil profile,” Lane says.

The Case IH 5-shank ripper still gets a workout from year to year behind a Cat Challenger 765 tractor as Lane seeks to break through hardpan areas, a practice he says has significantly improved water infiltration in his clay soil fields.

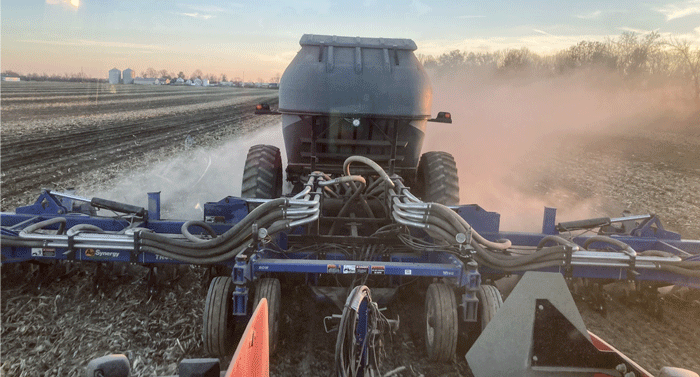

HEAVY HAULER. In addition to the Kinze strip-tiller, Lane now runs an AgSynergy shank strip-till bar with rolling closer wheels and a mounted 9-ton Montag dry fertilizer unit for deep-strip building in the fall. Photo: Dan Lane

“The first year I banded 100 pounds of MAP (monammonium sulfate) and 100 pounds of phosphorus (P),” he says. “At the time that was $45 an acre, and corn yields immediately jumped from our usual 145-170 bushels to 195-210.”

In those early years, the Lanes were still side-dressing with anhydrous ammonia, a practice they have since abandoned.

“We continued extensive soil and tissue testing as we began banding fertilizer and found that calcium is the ‘trucker’ of all nutrients into the corn plant,” he says. “We began banding calcium sulfate (gypsum), and by 2011, the tissue tests began coming back with evidence of increased uptake of magnesium, P and manganese.”

That was about the time Lane decided to double up on the 100 pounds of MAP and 100 pounds of P with spring and fall applications, along with 100 pounds of gypsum. In addition, he now includes 25-30 pounds per acre of chicken manure crumbles with his dry fertilizers.

“The first year we used the Kinze strip-till bar with dry fertilizer placement, we dropped the anhydrous ammonia application and went with Y-drops off our Hagie front-boom high-boy, applying 40 gallons of 28% N liquid fertilizer on V-10 corn, along with humates and a home-grown biological product. Yields immediately jumped up to 260-280 bushels per acre, with some areas pushing 300 bushels,” he says.

Nutrient Management

“My fertilizer decisions are ROI driven and consistently include MAP and potassium sulfate,” he says. “I’m convinced 100 pounds of potassium sulfate can do what 200 pounds of potassium chlorate does in my fields. Also, it’s important to get those nutrients below the plant where the roots can interact with them easily.”

The spring strip-till operation ahead of corn typically will see 100 pounds of MAP, 100 pounds of potassium sulfate, 50 pounds of a micronutrient mix of zinc, boron, manganese, magnesium, iron and copper along with 100 pounds of gypsum if pH is high or neutral. He uses pelletized lime when pH is low.

At planting, Lane will apply about 200 pounds of urea 2-by-2 or 25 gallons of liquid 28% through the planter, along with kelp, liquid humate and sugar to boost biological activity in the soil.

When corn is 8-10 inches tall, he applies a dry broadcast of ammonium sulfate, then returns at V10 with the Y-drop 28% N application with more humates, kelp and sugar.

“We’re not working the entire field which results in significant savings, plus we’re not disturbing the microbes in the soil between the rows…”

Overall, Lane generally fertilizes for 250-bushel yield averages across the farm and says every year is different because of weather. However, strip-till and banding have helped him cut fertilizer rates per bushel of production by a third while maintaining and growing yields over his conventional farming days.

“Even with our high-yielding corn I think my fertility program costs me an average of $50 per acre less than what many growers spend,” he says.

After harvest, Lane typically follows the combine with the Case IH 450 QuadTrac and a 25-foot Horsch Joker vertical tillage machine in preparation for fall-built strips, which usually run 6-8 inches deep behind the Ag Synergy machine.

“With 40,000 plants per acre of high-yielding corn, there is a tremendous amount of residue to handle, so the Joker helps us start that material decomposing as early as possible,” he says.

By spring in many seasons, Lane’s fall-built strips will have become a bit stale, and he will freshen them with a 2-4 inch pass with the Kinze to facilitate smooth planting.

Interplanting Benefits

While Lane has dropped cover crops in his management, he has taken a different direction on corn-soybean rotation. For the past 3 years, he’s been interplanting corn and soybeans in the same field — 30 feet of soybeans and 20 feet of corn.

“The edge effect of interplanted strips seems to allow more light onto the corn, and we’ve seen consistent 30-50 bushels per acre yield increases because of it,” Lane says. “The soybeans take an 8-10 bushel hit, however, especially planted next to traditional hybrids, but we’re making up for it with corn yield.”

Lane says he planted short corn last season in some interplanted fields and was impressed with the better performance of adjacent soybeans because of additional sunlight.

“The shorter corns only reached about 7 feet tall and didn’t shade the beans as much,” he says. “That convinced us that shade certainly hinders soybean yields, so for 2023 we’re going to interplant 20-by-20 to test the improvement.

Lane says he’s also banding nutrients on some soybean acres and seeing yield increases of 10-15 bushels per acre.

“Beans like a lot of P, calcium and sulfur, not just potassium, and we see a regular yield bump from the practice,” he says.

Environmental Benefits

Lane says his method of farming today has made substantial changes in the farm’s runoff into the Upper Scioto River watershed, which eventually drains into the Ohio River.

“Many people are fighting the extra water we’ve had to handle from heavy rains, but we seem to have much better water infiltration in our fields by strip-tilling and regular in-row ripping. Also, we have grassed water ways that help alleviate erosion, although we, too, must do annual repairs from heavy rains,” he says.

In the 2018 AFT soil health economic study, USDA’s Nutrient Tracking Tool showed the conservation efforts adopted by Homewood Farms since it was converted from conventional tillage reduced N, P, and sediment losses by 35%, 84% and 99% respectively.

“We also see improvements in soil health with the return of large populations of night crawlers,” Lane says. “By using strip-till we’re not working the entire field which results in significant savings in fuel burned. Plus, we’re not disturbing the microbes in the soil between the rows.”